Honored to receive the ASME Rising Stars in Mechanical Engineering Award at IMECE 2025 Conference in Memphis, thanks to Dr. Kwon for the nomination and the committee, and thanks to my students working on the project!

Honored to receive the ASME Rising Stars in Mechanical Engineering Award at IMECE 2025 Conference in Memphis, thanks to Dr. Kwon for the nomination and the committee, and thanks to my students working on the project!

SDSU 2025 Engineering Graduate Research Symposium

Qingqing received the MIT Rising Stars in Mechanical Engineering award, Congratulations!

we have 1 opening for joint Ph.D. student (SDSU & UCSD), students with background in 3D printing and materials science are preferred.

The application deadline is December 1, 2025.

The detail of JDP program is here: https://www.engineering.sdsu.edu/admissions/joint-doctoral/mechanical-aerospace

Ideal Candidate Qualifications:

What We Offer:

How to Apply:

Interested applicants should directly contact Dr. Yang Yang at yyang10@sdsu.edu. Please include the following in your email:

Projects demo for ME 596 course

ME 596 Additive Manufacturing (Fall 2025)

ME 220 Dynamics (Fall 2025)

ME 200 Statics (Spring 2025)

ME 220 Dynamics (Spring 2025)

ME 596 Additive Manufacturing (Fall 2024)

ME 240 Intro to Eng- materials (Fall 2024)

ME 681Biomaterials (Spring 2024)

ME 596 Additive Manufacturing (Fall 2023)

ME 240 Introduction to Engineering material (Fall 2023)

ME 220 Dynamics (Spring 2023)

ME 681 Biomaterials (Spring 2023)

ME 220 Dynamics (Fall 2022)

ME 240 Introduction to Engineering material (Fall 2022)

ME 241 Materials Lab (Spring 2022)

ME 681 Biomaterials (Spring 2022)

ME 640 Nanomaterials (Spring 2021)

ME 240 Introduction to Engineering material (Fall 2020)

ME 240 Introduction to Engineering material (Spring 2020)

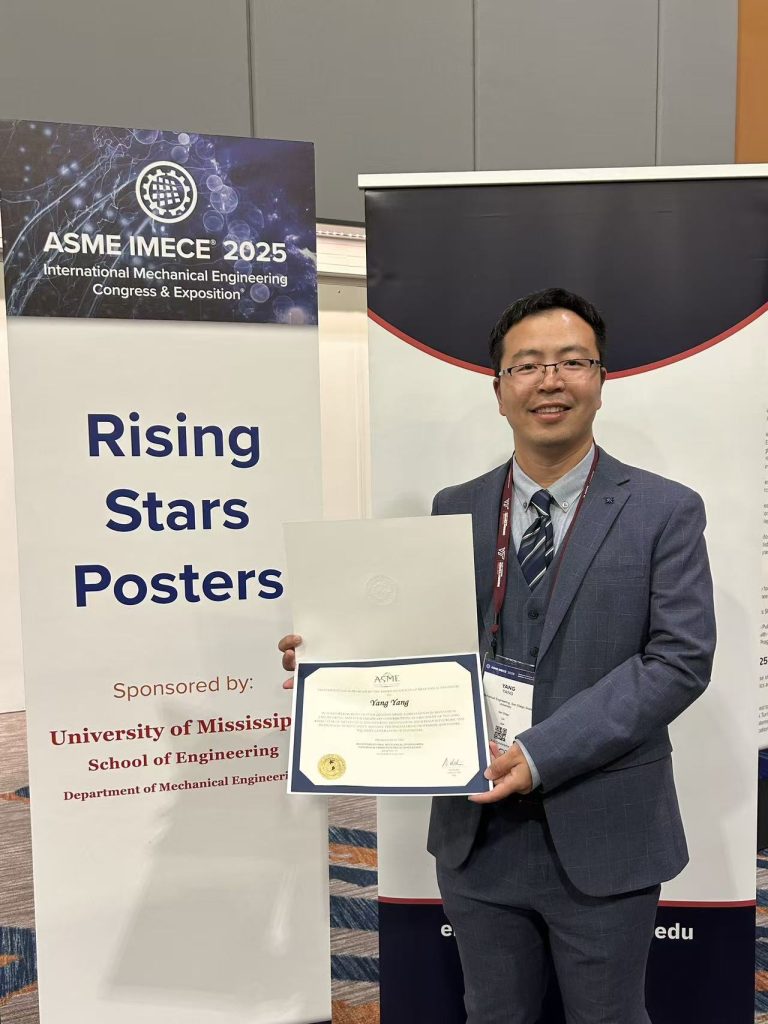

3D printing of bone implants using hydroxyapatite (HAP) or its composites, like HATCP, is revolutionizing orthopedics. This technique enables the creation of patient-specific, biocompatible scaffolds that perfectly match bone defects. These printed structures are osteoconductive, actively encouraging new bone growth and integration for superior healing outcomes.

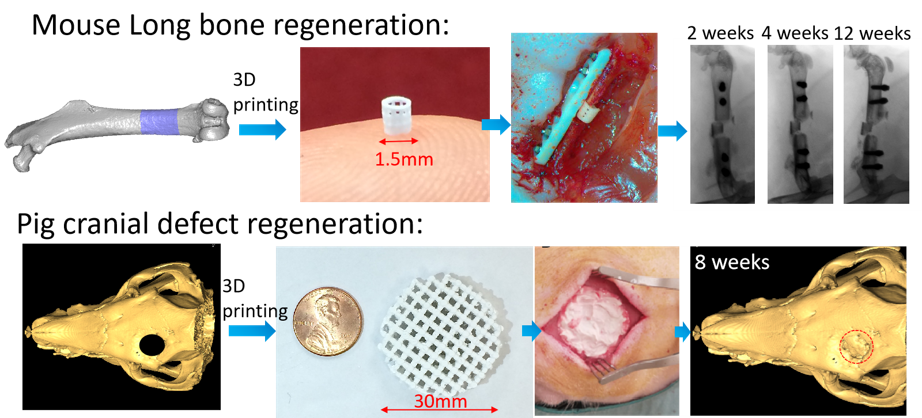

we present a strategy to build a star-nose-inspired sensor with stretchable and twistable structure, where the nose’s ray-like parallel polyimide films were fabricated by electrospinning and chemical silver coating. The sensor is finally encapsulated in PDMS and its sensitivity is significantly improved due to the design of bio-inspired parallel films. The bio-inspired sensor finally exhibits ultra-light, ultra-thin, and high sensitivity (Gauge Factor (GF) ~ 4000) characteristics, ensuring a perfect fit for human skin to achieve stretch, twist (https://www.sciencedirect.com/science/article/pii/S2211285520311332)

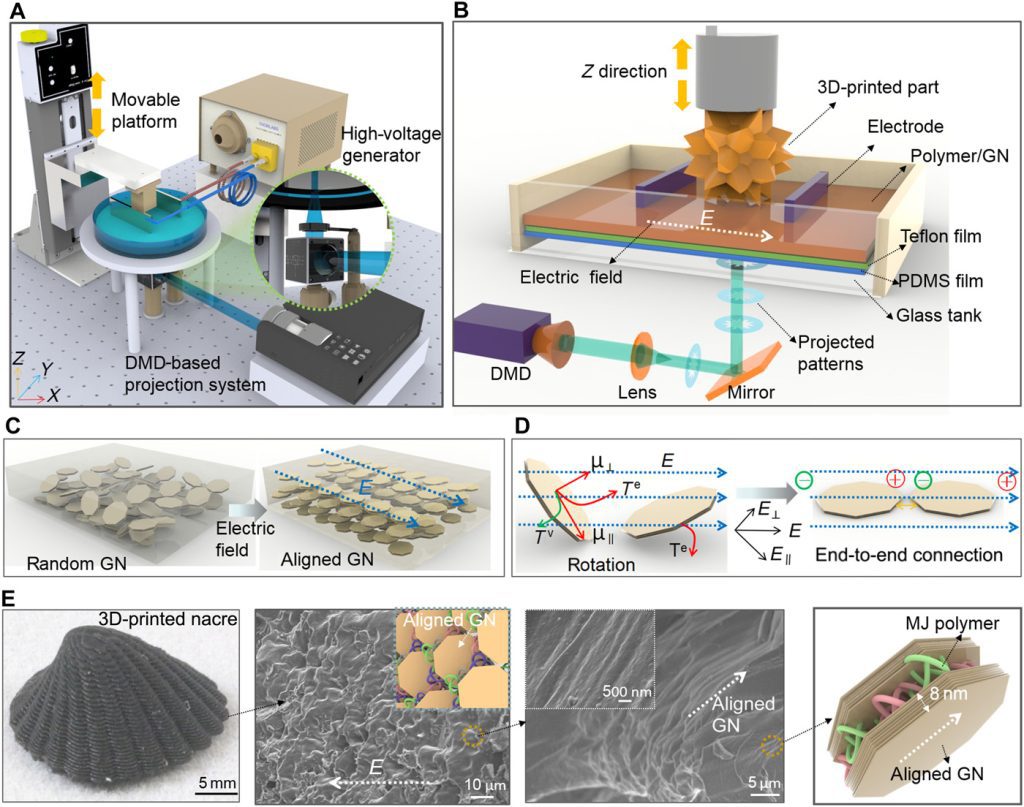

We present a route to build nacre-inspired hierarchical structures with complex three-dimensional (3D) shapes by electrically assisted 3D printing. Graphene nanoplatelet (GN) is aligned by electric field (433V/cm) during 3D printing and act as brick with polymer matrix in between as mortar. The 3D printed structures with aligned GN show reinforced mechanical property as well as 100 times reduced electrical resistance compared with random GN with the same loading. The 3D printed nacre with aligned GN (2wt%) shows lightweight (1.06g/cm3) while comparable specific toughness and strength with natural nacre. Besides, 3D printed lightweight smart armor with aligned GN can sense its own damage with a hesitated resistance change as well as protective high impact resistance. This study also highlights interesting possibilities in achieving bioinspired structures with integrated mechanical reinforcement and electrical self-sensing in biomedical, aerospace engineering as well as military and sports armors.(https://www.science.org/doi/full/10.1126/sciadv.aau9490)

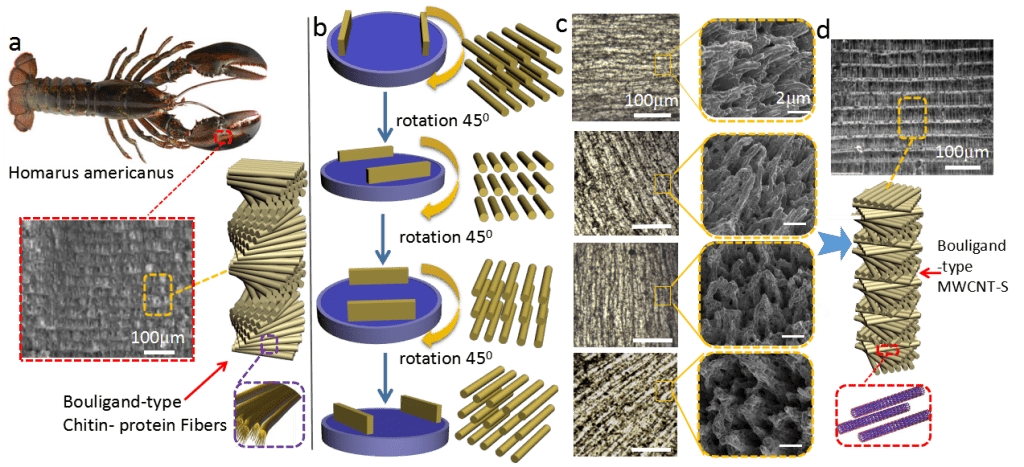

Here we report an electrically assisted additive manufacturing approach that bio-mimic the Bouligand structure in natural creatures to create highly impact resistant architectures. The alignment of surface modified Multi-walled Carbon Nanotubes (MWCNT-S) was controlled by rotating electric field during printing. (https://advanced.onlinelibrary.wiley.com/doi/abs/10.1002/adma.201605750?scrollTo=references)